Services

From conception to completion, we offer a complete solution to your needs, using only the highest quality materials available to safeguard the desired results.

Floor screeding

Self-Levelling Compounds

Comprising of cementitious and latex products which are mainly applied to the top layer of a screed where a greater degree of tolerance is required for the application of sensitive floor finishes.

Thicknesses vary from 1mm to 40mm in a single application. Most floor levelling compounds are fast drying polymer modifications.

Reinforced Screeds

The purpose of reinforced screeds is to support the stress upon the screed during the drying process and help prevent curling, cracking and shrinkage that are naturally inherent within the cementitious properties of the screed.

Reinforcement can be applied in various ways and generally require the use of fibres or a metal mesh.

Traditional Floor Screeding

Sand & Cement floor screeding can be used in: Residential Dwellings, Commercial Units, Schools, Hospitals, Retail Units, Sports Facilities, Airports & virtually any area where a level surface is required to receive a final floor finish.

Used for: Bonded, Unbonded, Floating, Reinforced and Heated Screeds.

Free Flowing Screeds

Free Flowing / liquid Screeds comprise sharp sand aggregate, cement or anhydrite binder & water. These type of screeds can be installed quickly and can be installed in both residential and commercial environments.

Used for: Bonded, Unbonded, Floating & Heated Screeds, Accelerated Drying Additives

Fast Drying Screeds and additives can be used where critical timescales and site conditions do not allow for the normal drying times of traditional screeds.

We recommend that you discuss your requirement with your UKS Group representative, who will provide you with details of the options available to you.

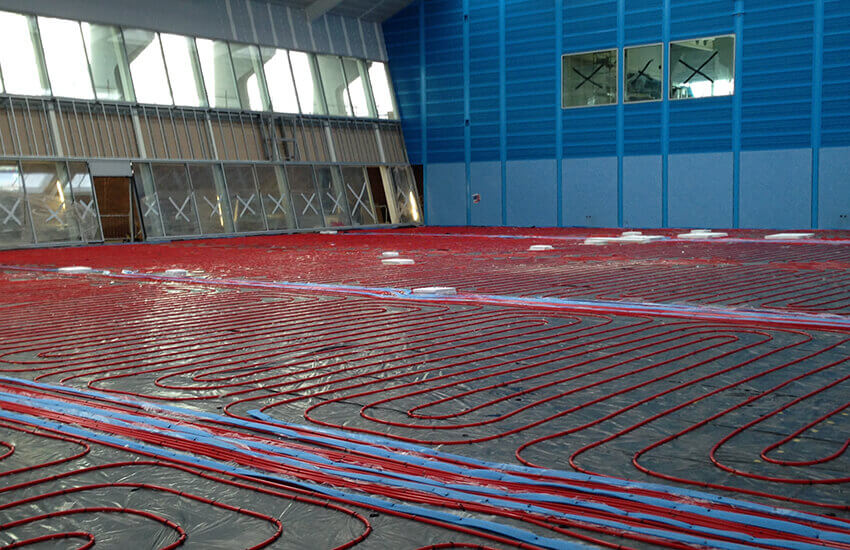

Underfloor Heating

Underfloor Heating

For environments where greater control is required for ambient temperature, Underfloor Systems using water can be set in reverse, using chilled or super chilled water to cool the environment, without the disadvantages associated with air cooling systems, such as expensive ducting, air pollution, noise and draughts.

As the fastest growing segment within the heating industry, Underfloor Heating is increasingly being used within the Educational and Health Care sectors, as well as Residential and Retail developments. Underfloor Heating offers significant benefits over traditional heating systems both in terms of sustainability, aesthetic quality and running costs, reducing energy use by 15%-40% compared with standard radiators.

Another huge advantage of modern Underfloor Heating systems is that they can also be easily adapted for use with alternative and renewable energy sources such as Ground/Air Source Heat Pumps, biomass boilers and solar energy systems.

Underfloor Heating systems also offer effective and fully controllable radiant heating to your environment without the need for unsightly wall mounted radiators, giving greater freedom for distinctive internal design. In addition, the radiant heat produced reduces air circulation and humidity which in turn reduces airborne allergens and the likelihood of dust mites.

Underfloor Cooling

For environments where greater control is required for ambient temperature, Underfloor Systems using water can be set in reverse, using chilled or super chilled water to cool the environment, without the disadvantages associated with air cooling systems, such as expensive ducting, air pollution, noise and draughts.

UFH Systems

UKS Group incorporates three different systems depending on project requirements.

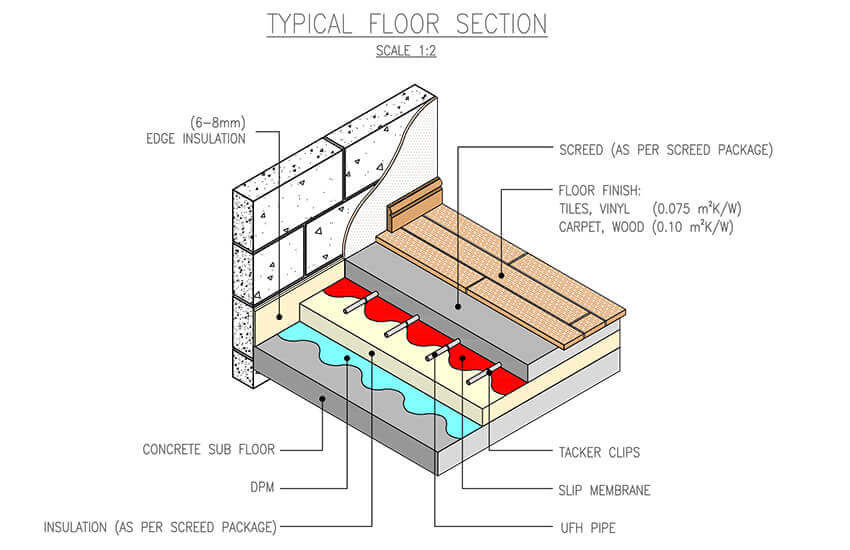

Tacker System

The Tacker system is the most widely used in the industry due to its versatility and ease of installation, and can be used with both sand & cement and liquid screed.

This system uses plastic clips to secure the underfloor heating pipe to laminated insulation panels. The floor insulation panels are constructed from either expanded polystyrene EPS or PIR (polyisocyanurate).

The insulation panels have a hessian-based polyethylene foil laminated to the surface of the panel. The foil provides a gridded reference for correct pipe spacing and fixing.

Wire Grid System

The wire grid system is employed when the Tacker floor insulation panels are not used.

Suitable alternative floor insulation is overlaid with a vapour barrier, with edge insulation applied to all walls in preparation for the installation. A wire grid with a 200mm square mesh pattern is laid butt jointed onto the floor insulation.

The PEX or PE-RT pipework is then laid out on the grid in the required configuration and secured to the grid with plastic securing ties.

Clip Rail System

The Clip Rail system comprises plastic pipe-locating rails, which have a self-adhesive backing for easier installation, are fitted to the floor insulation, into which the pipework is clipped.

These rails are available for both 16mm and 20mm pipe. Edge and floor insulation is then overlaid with a plastic moisture barrier to cover the floor area. The Clip Rails are then secured into the floor insulation with fixing pins.

As with the wire grid system the PEX or PE-RT pipework is then laid out in the required configuration.

All systems are then filled with water and pressure tested prior to the floor screed being laid.

Acoustic Solutions

Whether it’s within the Leisure Industry, Education and Health Care sectors or simply residential dwellings, modern day living has created noise levels which can be detrimental to health and wellbeing.

The use of technology, the growth of inner city living, apartment developments and the trend towards hard flooring finishes all contribute to issues of unwanted sound that can distract us from our normal daily activities.

UKS Group offer consultation to determine the best way to minimise noise levels, including recommended layouts, ensuring each area is fitted with the correct material to maximise sound insulation and a reduction in ambient noise levels.